Climate protection in the spin cycle

Science and industry jointly test a new technology for CO2 capture in the cement industry

Imagine a giant washing machine that washes CO2 from flue gases instead of dirt from clothes. This is the idea behind a new process being researched by TU Berlin together with thyssenkrupp Uhde GmbH and the building materials group Holcim. The aim: an energy-efficient solution to reduce CO2 emissions in the cement industry, which is responsible for eight percent of global industrial emissions. During production, limestone is burned, releasing large quantities of CO2, i.e. carbon dioxide - a process that cannot be avoided.

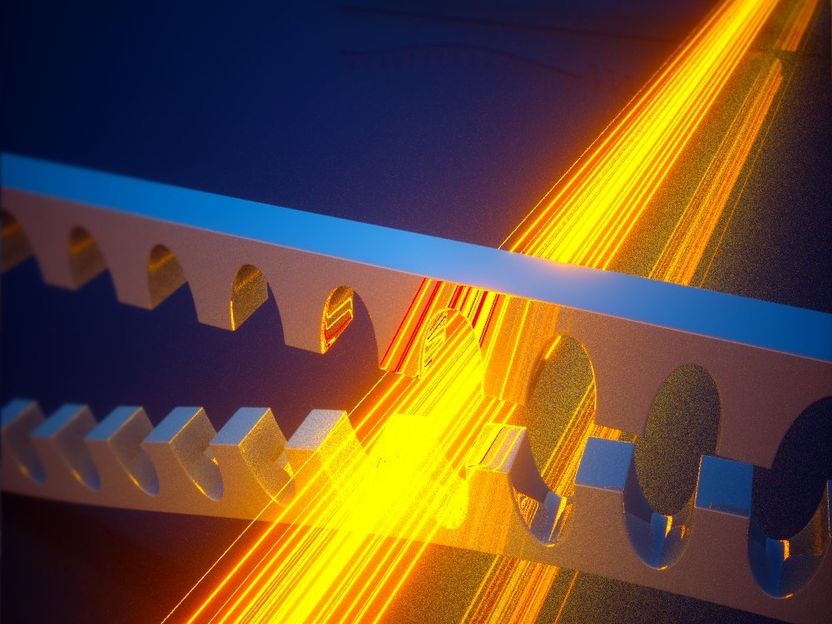

The approach that the cooperation partners are pursuing is based on so-called amine scrubbing, a chemical absorption process that is carried out in a rotating apparatus. "You can think of it like a washing machine," explains Jens-Uwe Repke, Head of the Dynamics and Operation of Technical Systems department. "The exhaust gas is fed into a rotating drum called a packing. There it comes into contact with a special scrubbing liquid, the amine solution, whereby the CO2 is bound in the liquid."

Centrifugal forces, similar to a carousel

The special feature of the new technology is the rotating packing elements made of metal foam, which offer a large surface area in a small space. "The rotating internals use centrifugal forces, similar to a carousel. They ensure that the liquid is guided through the metal foam, and intensive mixing of gas and detergent is achieved here," says Olaf von Morstein, project coordinator at thyssenkrupp Uhde. "This allows us to filter more CO2 out of the exhaust gases in a shorter space of time - and with less energy input." Thanks to the rotating apparatus, concentrated washing solutions are also used, which significantly increases the CO2 absorption capacity per liter of detergent. The rotation also allows flexible adaptation to different production conditions by controlling the speed.

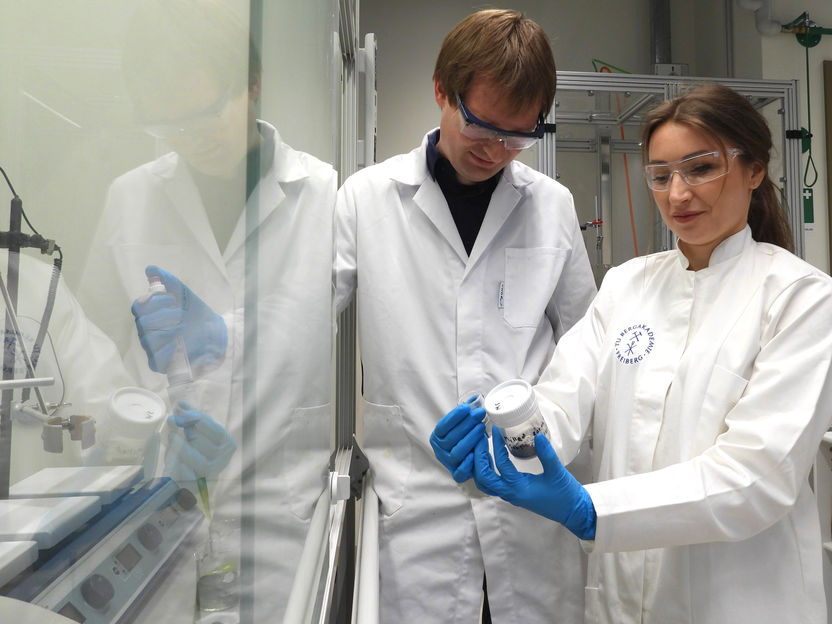

"We combine basic research with practical application here," says Jens-Uwe Repke. "Our models work in the laboratory - but it is crucial that the technology also proves itself in industry." The process is currently being tested with real exhaust gas streams in a pilot plant at the Holcim cement works in Beckum, North Rhine-Westphalia. "This allows us to ensure that there are no unexpected problems on an industrial scale," says Florian Kleinwächter, Corporate Developer at Holcim.

CO2 reduction of more than 90 percent

The results are promising: the system can scrub more than 90 percent of the carbon dioxide from the exhaust gases. The TU team is also working on mathematical models that will enable the technology to be scaled up to an industrial scale. "Our aim is for such systems to be used as standard in the cement industry in the future," says Repke. "If I drive past a plant in ten years' time and see that this technology is in use there - that would be the fulfillment of a dream for me as a scientist."

The project shows how important cooperation between universities and companies is. Repke's department has been working successfully with thyssenkrupp Uhde for a long time. His department also cooperates intensively with other industrial partners and universities. "In Germany, we still have the great advantage that research and industry are closely networked," says Repke. Students and doctoral candidates at TU Berlin work directly with experts from thyssenkrupp Uhde and Holcim. Both sides benefit from the transfer of knowledge: Industry receives practical solutions and it is ensured that research not only works in the laboratory, but also in practice.

"Our carbon capture projects quickly cost several hundred million euros," explains Kleinwächter. "That's why we need the certainty that the technology will also work reliably in real-life operation. Only through close cooperation can we drive innovation forward and continue on the path to climate neutrality."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Most read news

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Milestone in diaper recycling: degrading cellulose in composite materials succeeded - Breakthrough with the help of enzymes

Siemens and TURN2X join forces to scale up green energy production - Partnership directly contributes to expanding the availability of green energy alternatives

Renewable Materials Conference 2025: Nominees for the Innovation Award Unveiled

New method for sustainable recycling of rare earths from electrolysers - Turning old into new

Air Products and thyssenkrupp Sign Exclusive Strategic Cooperation Agreement - World-Scale Electrolysis Plants to Generate Green Hydrogen

Pfeiffer Vacuum Opens New Leak Detection and Vacuum Technology Facility in Indianapolis, Indiana

Using artificial intelligence to control digital manufacturing - Researchers train a machine-learning model to monitor and adjust the 3D printing process to correct errors in real-time

You can make carbon dioxide filters with a 3D printer

Carbon capture method plucks CO2 straight from the air - Using humidity-powered technology, researchers found several new ions that facilitate low-energy carbon sequestration

Climeworks and Svante collaborate in development and supply for direct air capture - Both companies agree to collaborate on three major CO₂ removal projects

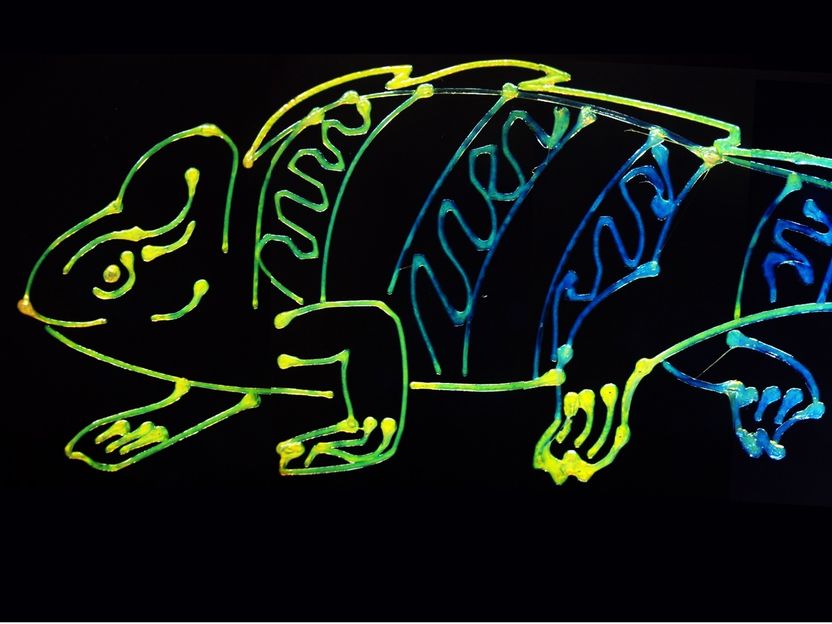

Chameleons inspire new multicolor 3D-printing technology - Researchers developed a sustainable technique to 3D print multiple dynamic colors from a single ink