Electroactive polymers for heating and cooling

The temperature converters among electroactive materials

electroactive polymers react to forces, deformations, and temperature changes with electrical signals. They can also deform or change their temperature under electrical voltage. Targeted temperature changes are particularly interesting for heating and cooling systems. Electrocaloric polymers are the key to this. Researchers at the Fraunhofer Institute for Applied Polymer Research IAP are developing electrocaloric materials and processing them into functional components. As the heart of an optimized overall system, they are an important basis for the future development of efficient and compact heating and cooling systems that do not require harmful refrigerants.

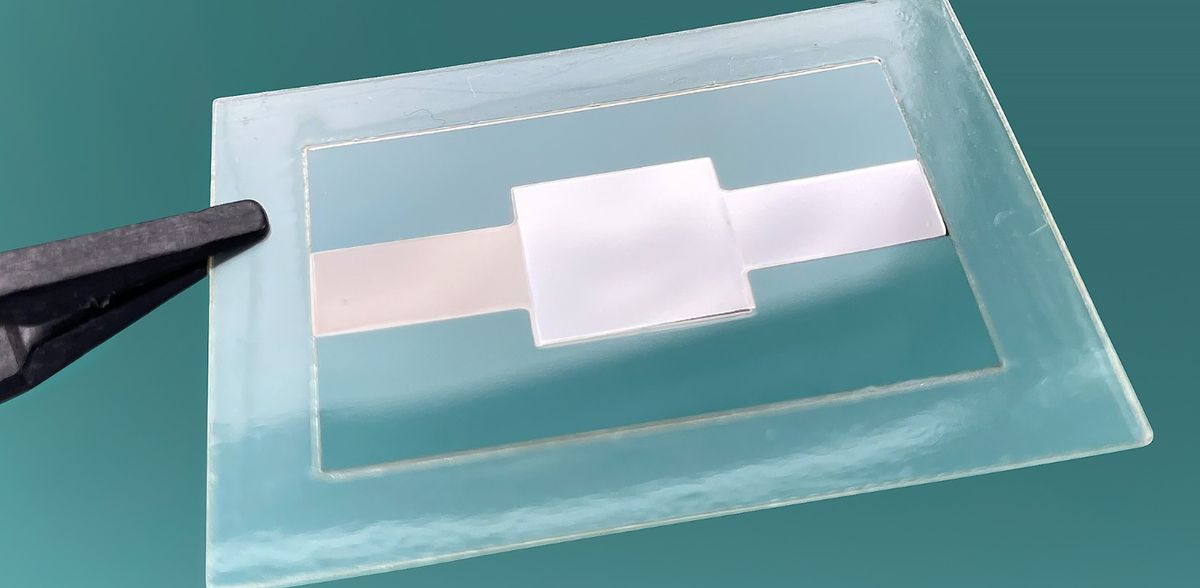

Research scientists at Fraunhofer IAP have developed electrocaloric polymer films with a very low thickness of only four micrometers and processed them into multilayer components. In the future, they will be used in various systems for heating and cooling. For example, in heat pumps for temperature control in vehicle interiors, battery modules, electronic components, control cabinets, or laser systems. “Low layer thicknesses are crucial for operating electrocaloric systems at voltages well below one kilovolt,” explains Dr. Michael Wegener, head of the Sensors and Actuators department at Fraunhofer IAP. Together with his team, he develops and improves various electroactive polymers (EAPs) for a wide range of applications. These include electromechanical sensors and actuators for applications in soft robotics and automation, sound and vibration detectors, ultrasonic transducers, pyroelectric layers for infrared sensors, and electrocaloric materials for heating and cooling.

Electrocaloric polymers: the temperature converters among electroactive materials

Electrocaloric polymers react to changes in electrical voltage with changes in temperature: the sudden application of an electric field leads to a specific, sudden rise in temperature, which increases the greater the change in the electric field. This is due to polar structures in the material, which are forced into an orderly alignment by the electric field and release energy in the process. Conversely, they absorb energy again as soon as the electric field is switched off. The material cools down abruptly to the same extent. For the technical use of electrocaloric materials in heating and cooling systems, these processes must be repeated at high frequencies and controlled in such a way that heating and cooling take place in different environments. Only then can a heat pump with usable, permanently warm and cold areas be created. Several properties of the material are crucial for high electrocaloric performance, including a large change in electrical polarization, high dielectric strength, low thermal losses, and good mechanical stability.

Material development: Tailor-made solutions for electrocaloric applications

Researchers at Fraunhofer IAP are specifically improving the properties of electrocaloric materials and adapting the components developed from them for individual applications. The focus is on chemical and physical modifications to PVDF terpolymers and the development of components consisting of several layers of thin electrocaloric polymer films that are optimized for the highest possible temperature changes.

High-precision thin-film technology: The key to efficiency

Electroactive polymers place high demands on thin film processing and the construction of multilayer systems. Particular challenges include the homogeneity of the polymer films and maintaining high electrical strength and the desired functional properties – in this case, the large temperature changes. "First, we optimize the materials through chemical modifications, thermal or radiation-induced post-treatment, or the addition of fillers. We then develop special manufacturing methods such as doctor blading, coating, or printing processes and optimize the manufacturing parameters to produce thin films with the desired properties. In the final step, we focus on optimizing further processes, such as the mechanical stretching of the films or the application of electrode systems with suitable thermal properties," says Wegener, summarizing the development phases for electrocaloric polymer films.

Stacking processes: Multilayer structures for efficient heating and cooling applications

An essential aspect is the stacking of individual films into multilayer structures, known as components. Stacking several films with electrodes in between increases the amount of electrocaloric polymer that interacts with the electric field without increasing the required operating voltage. This type of structure and the use of many such components provide the appropriate thermal mass to efficiently utilize electrocaloric polymers in heating and cooling systems.

Electrocaloric: Innovative technology in focus

The newly developed electrocaloric polymer films and components are the result of the Fraunhofer flagship project Electrocaloric Heat Pumps (ElKaWe). In this project, research scientists from six Fraunhofer institutes worked together to develop innovative polymer-based and ceramic electrocaloric materials as well as high-performance control electronics. Heat pumps based on electrocaloric materials have the potential to become a more environmentally friendly and efficient solution for heating and cooling, replacing conventional systems that use compressors and climate-damaging refrigerants.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

3D printer as a reactor for new materials - Chemist Katharina Ehrmann receives the Dr. Ernst Fehrer Prize

LIKAT chemist receives award for digital data management and AI in catalysis

Jochen Block Award 2025 for Dr. Thomas Seidensticker - Start-up “simplyfined” wants to make the chemical industry more sustainable

New general manager at Oxford Instruments WITec in Ulm

Michael Grosse to succeed Joachim Kreuzburg as Chief Executive Officer of Sartorius AG - Grosse to take over as Group CEO on July 1, 2025

Appointment of Dr. Werner Ponikwar as CEO of thyssenkrupp nucera extended by five years - Dr. Stefan Hahn to become new CFO

Key Position Changes at Brückner Group - A Veteran Departs

DMC Biotechnologies announces Dr. Jim Flatt as CEO - DMC seeking to transform how the world makes chemicals

Insights into the Nanoworld: Volker Deckert Receives the 2025 Lamb Award - A Pioneer in Tip-Enhanced Raman Spectroscopy

Innovative Methods for Biomolecular Mass Spectrometry - Fresenius Award for Kathrin Breuker

Leadership change at KRAHN Chemie - Martin John takes over as CEO