H.C. Starck Tungsten receives millions in funding for battery recycling

Over 60 million euros for the recycling of battery black mass

The federal and state governments intend to provide over 60 million euros to promote the recycling of battery black mass at H.C. Starck Tungsten in Goslar. This decision was confirmed by Lower Saxony's Economics Minister Olaf Lies, also on behalf of the Federal Ministry of Economics, to company CEO Dr. Hady Seyeda at the Hannover Messe.

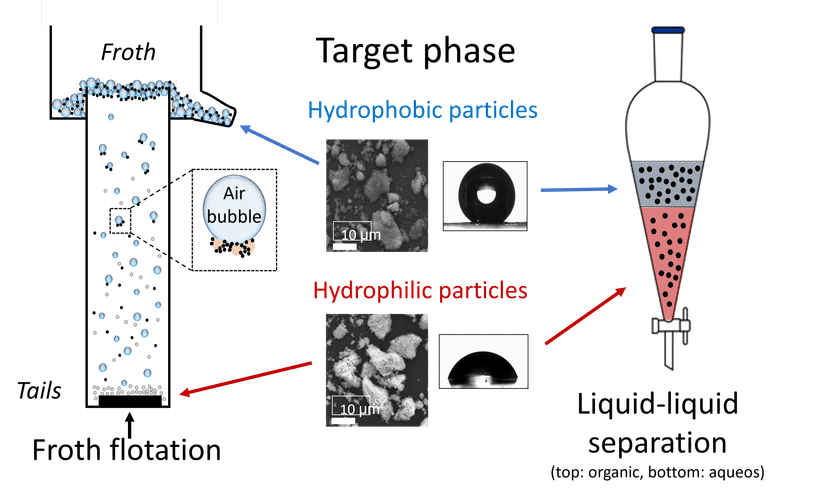

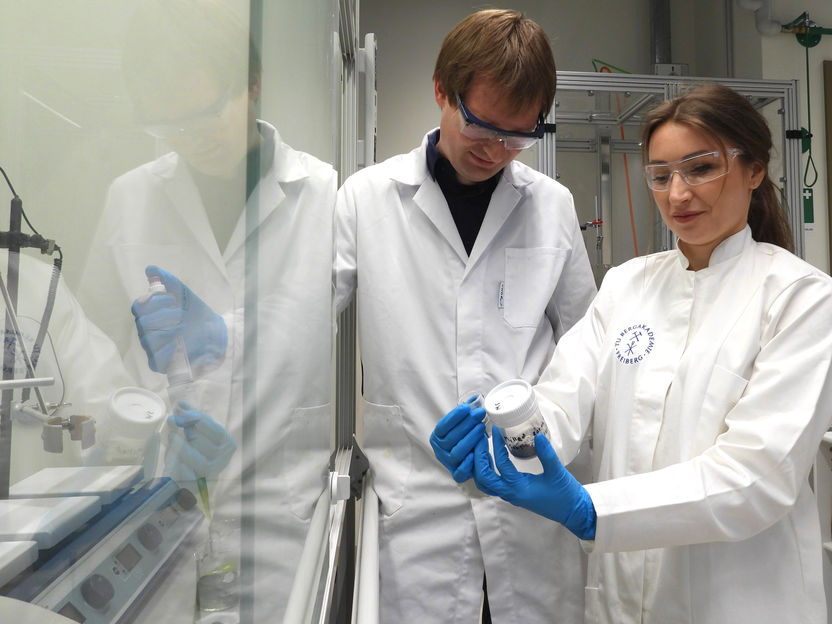

At the heart of the project is an innovative, particularly efficient process for recovering valuable metals from so-called "black mass" - the ground-up components of used lithium-ion batteries after the casing has been removed - which H.C. Starck Tungsten has developed.

The process, for which six patent applications are pending, achieves a significantly better raw material yield compared to established methods, while consuming considerably less auxiliary materials and energy. In addition, only a tenth of theCO2 emissions are produced that would be generated by mining primary lithium, nickel, cobalt and manganese.

Parent company supports project

For application on an industrial scale, H.C. Starck Tungsten is considering the construction of a plant in the Oker Metallurgical Park with an investment volume of around 340 million euros. The associated funding application was also supported by the parent company Mitsubishi Materials Corporation.

If the further project steps go according to plan, the two-year construction work could begin in the first half of 2027. The target recycling capacity is around 20,000 tons of black mass per year, comparable to the battery content of around 100,000 small electric cars.

Regional, national and European sustainability

The funds, 70% of which are being provided by the Federal Ministry for Economic Affairs and Climate Protection and 30% by the state of Lower Saxony, are being awarded as part of the EU directive on the "Resilience and sustainability of the battery cell production ecosystem". Accordingly, they are intended to help establish and expand production capacities along the battery value chain in Germany and the European Union, secure employment and value creation in Germany and ultimately enable climate-friendly mass production of sustainably produced battery cells in Europe.

At regional level, the funding decision aims to strengthen Goslar as a location for innovation, business and production, to cushion the negative effects of structural change and to promote the operation of particularly sustainable industrial plants.

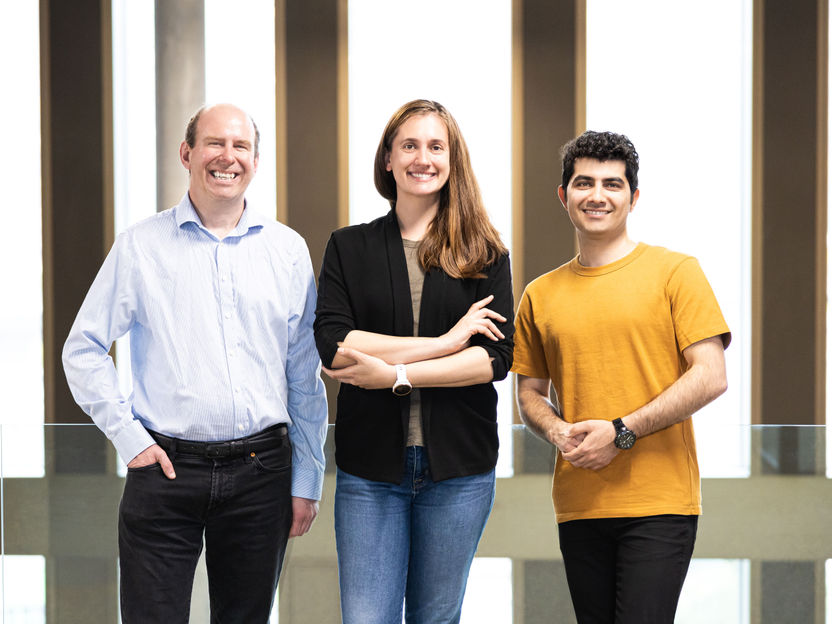

Dr. Hady Seyeda, CEO of H.C. Starck Tungsten, says: "This comprehensive funding commitment marks an important step towards the industrial use of our innovative black mass recycling technology. We are delighted that the federal and state governments are supporting the realization of our concept in such a concrete way."

Lower Saxony's Minister of Economic Affairs, Olaf Lies, added: "Southern Lower Saxony and Goslar in particular have a strong tradition in ore mining and metal processing. The state of Lower Saxony has long supported the region in becoming internationally competitive in the field of recycling and optimizing the value chains in the recycling of lithium-ion batteries. The funding of H.C. Starck Tungsten is a milestone for environmentally friendly recycling of black mass on an industrial scale and thus makes an important contribution to securing raw materials and safeguarding industrial jobs."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.