How much microplastic is generated during mountain biking?

First concrete figures on the abrasion of mountain bike tyres in off-road conditions: findings help to better understand the global microplastic cycle

For years, it has been known that tyre wear from motor vehicles is a major contributor to microplastic pollution. Approximately 11 grams of microplastic are released per 100 kilometres driven, accounting for about 57% of microplastic pollution from road traffic and roughly 35% of total microplastic pollution in Germany. In contrast, cycling is considered an environmentally friendly mode of transport and is also a popular recreational activity. Mountain biking, in particular, has been growing in popularity, with around 20% of the German population now participating in this sport – sometimes in pristine natural environments. However, no data has been available on the quantity and significance of tyre abrasion from mountain biking. To gain a broader understanding of the environmental impact of cycling, researchers at the Chair of Sport Ecology at the University of Bayreuth have now conducted the first study on the abrasion of mountain bike tyres.

For the study, a team led by doctoral researcher Fabian Sommer equipped nine mountain bikers with brand-new tyres. The participants then followed their usual riding habits while tracking their routes via GPS. At predetermined intervals, the tyres were weighed in the lab to measure and document material loss due to abrasion.

On average, the study found that tyre abrasion amounted to approximately 3.5 grams per 100 kilometres, equating to a per-capita abrasion rate of up to 88 grams per year. When scaled up to the total microplastic pollution in Germany, mountain bikes contribute to less than one percent. The researchers also observed that the abrasion rate was higher during the first 500 kilometres of riding with new tyres compared to after the 500-kilometre mark. According to the researchers, this could be due to the rounding of tyre edges and the relatively quick wear of excess material from the manufacturing process – the small hair-like structures found on new tyres.

"Our study provides the first reliable data on the amount of tyre abrasion from mountain bikes under real-world conditions. The results show that while mountain bike tyres release microplastics directly into nature, the amount is significantly lower compared to motorised vehicles. This highlights another advantage of cycling as a sustainable mode of transport," says Sommer.

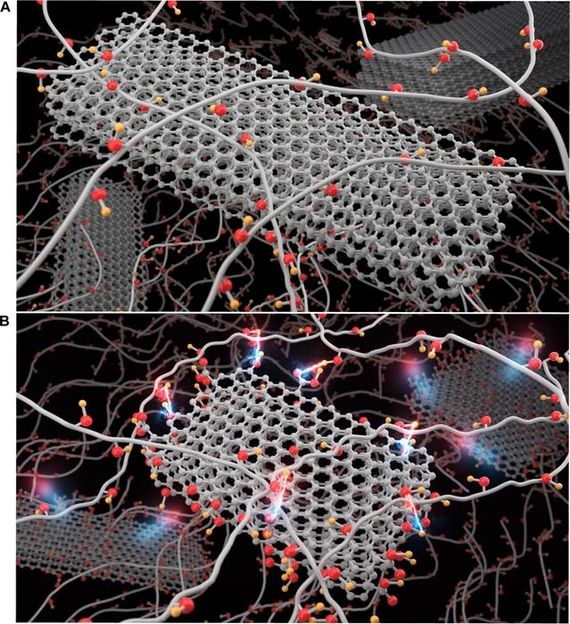

As part of ongoing research, a follow-up study is now being conducted, focusing on tyres from road bikes, gravel bikes, and mountain bikes/e-mountain bikes. This study aims to provide additional insights into the dynamics and rates of tyre abrasion for these different types of bicycles. In addition, environmental samples will be analysed in collaboration with the laboratory of Prof. Dr. Christian Laforsch from the Collaborative Research Centre 1357 Microplastics at the University of Bayreuth to better understand the impact of microplastics on the environment.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Improved Recycling of Plastic from Packaging Waste - Recycled plastic used in filaments for 3D printing

New study reveals polymers with flawed fillers boost heat transfer in plastics - Research team challenges the conventional wisdom that perfect fillers are better for making thermally conductive polymers

Marine litter: what biodegradable plastics can do to solve the problem - A third generation of biodegradable plastics could bring hope in the fight against plastic waste

French start-up develops biosourced polymer as a plastic alternative for industrial companies - Start-up portrait: Lactips - Natural revolution against microplastics in the industry

Twelve ideas for the defossilisation of the plastics industry - “Start-ups provide crucial impulses for the future of our industry”

Enhancing the Sustainability of Plastics Using Sulphur Waste

AI: A Game Changer for Plastic Packaging - Circular economy for packaging

Shipping of the future: biodegradable antifouling coatings for clean seas - Interdisciplinarity as the key to sustainable material innovation

CO₂ removal and storage: Which options are feasible and desirable? - A new framework helps to evaluate the feasibility of ocean-based CO2 removal processes and assesses their impact on humans and nature

Sustainable plastics containing flame retardants for use in closed-loop applications - New ways for recycling quotas

H.C. Starck Tungsten receives millions in funding for battery recycling - Over 60 million euros for the recycling of battery black mass