Milestone in diaper recycling: degrading cellulose in composite materials succeeded

Breakthrough with the help of enzymes

Paper, glass, plastic, even concrete: many materials are now recycled. For diapers, on the other hand, this is still almost impossible. Worldwide, less than one percent of all diapers are recycled - and this is despite the fact that diapers make up around ten percent of household waste (in care homes, this figure can rise to 70 percent). The challenge is separating the cellulose in the diapers from the superabsorbent material that absorbs the liquid. A team of researchers led by Dr. Anne Zeck, group leader at the NMI Natural and Medical Sciences Institute in Reutlingen, has now achieved a breakthrough with the help of enzymes as part of the Invest BW project Encycling.

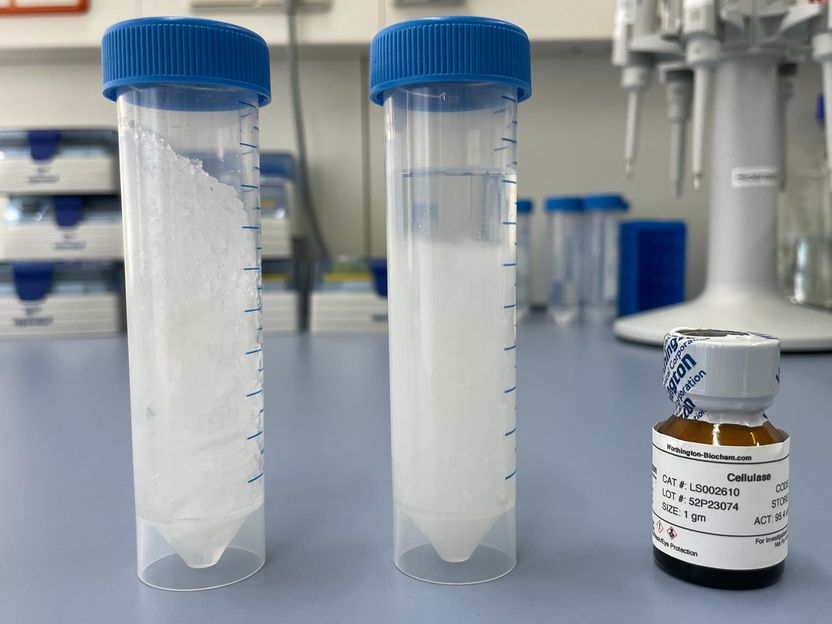

On the left, the diaper mass, which is extremely viscous after the addition of liquid. On the right, demixed after the addition of calcium chloride; after the liquid has been poured off, the enzymes (in the small jar) can break down the cellulose.

NMI

Mixture of cellulose and the superabsorber

Diapers are a so-called composite material. Inside them is a mixture of cellulose, which in this case is like absorbent cotton and is necessary for the most comfortable wearing experience possible, and the so-called superabsorber, which consists of the sodium salt of polyacrylic acid and can absorb many times its own weight in liquid. Both materials are easily recyclable on their own. In the case of diapers, however, they must first be separated. This is complicated - and unfortunately not possible for all manufacturers.

Extremely viscous mass

“When a liquid is added to this mixture of cellulose and superabsorbent material, the result is a gel-like mass. This makes it impossible to mix the mass properly and treat it with enzymes,” explains project manager Anne Zeck. By adding calcium chloride, the superabsorber releases the bound liquid again. The shredded diaper mass can now be mixed thoroughly.

Cellulose degradation is not new - but it is in diapers

The next step was to search for enzymes that can break down cellulose. “Two criteria are particularly important in this search: from a huge range of enzymes, we had to find those that are reliably able to convert cellulose into soluble sugar molecules in the very specific environment of a diaper. At the same time, however, these enzymes had to be not too expensive so that the technology had a realistic chance of succeeding on the market,” says Anne Zeck, describing the challenges. The company Candidum provided support in this search.

0.7 grams of enzymes break down 800 grams of cellulose

Anne Zeck's team added a total of 0.7 grams of the enzymes that were ultimately selected to 5.8 kilograms of diaper material, which they had previously shredded and soaked in water - because diapers end up in the trash in a used, i.e. damp, state. They shook this mixture for several days at 50 degrees Celsius. During this time, the enzymes broke down 800 grams of cellulose and produced sugar from it, which was removed with the aqueous phase. Five kilograms of the shredded diaper material, which mainly contains superabsorbents, remained.

A milestone - to be followed by others

In the next step, ARCUS Greencycling will test on a pilot plant scale (i.e. larger than a laboratory experiment, but smaller than an industrial production process) whether the low-cellulose composite material can be chemically recycled significantly better. Put simply, the question is whether this so-called pyrolysis (i.e. the splitting of the composite material into its original raw materials) and thus the return of the raw materials to the cycle is more successful. Ways of using the sugar-containing liquid as a material in the future are to be investigated. Water consumption also needs to be optimized. Only then will recycling be truly successful and make both ecological and economic sense. Nevertheless, the successful use of enzymes in a difficult environment is a milestone on the way there.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Siemens and TURN2X join forces to scale up green energy production - Partnership directly contributes to expanding the availability of green energy alternatives

Renewable Materials Conference 2025: Nominees for the Innovation Award Unveiled

New method for sustainable recycling of rare earths from electrolysers - Turning old into new

Air Products and thyssenkrupp Sign Exclusive Strategic Cooperation Agreement - World-Scale Electrolysis Plants to Generate Green Hydrogen

Pfeiffer Vacuum Opens New Leak Detection and Vacuum Technology Facility in Indianapolis, Indiana

Using artificial intelligence to control digital manufacturing - Researchers train a machine-learning model to monitor and adjust the 3D printing process to correct errors in real-time

You can make carbon dioxide filters with a 3D printer

Carbon capture method plucks CO2 straight from the air - Using humidity-powered technology, researchers found several new ions that facilitate low-energy carbon sequestration

Climeworks and Svante collaborate in development and supply for direct air capture - Both companies agree to collaborate on three major CO₂ removal projects

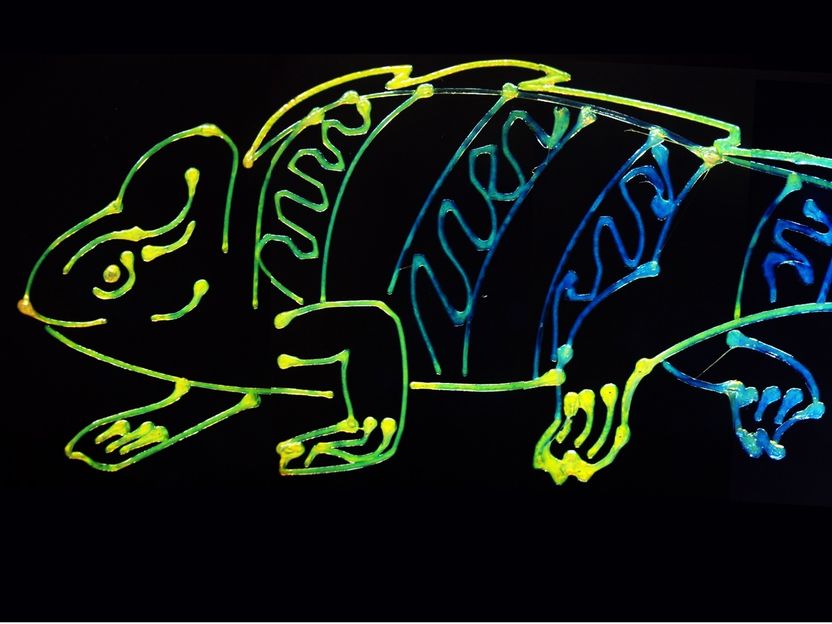

Chameleons inspire new multicolor 3D-printing technology - Researchers developed a sustainable technique to 3D print multiple dynamic colors from a single ink

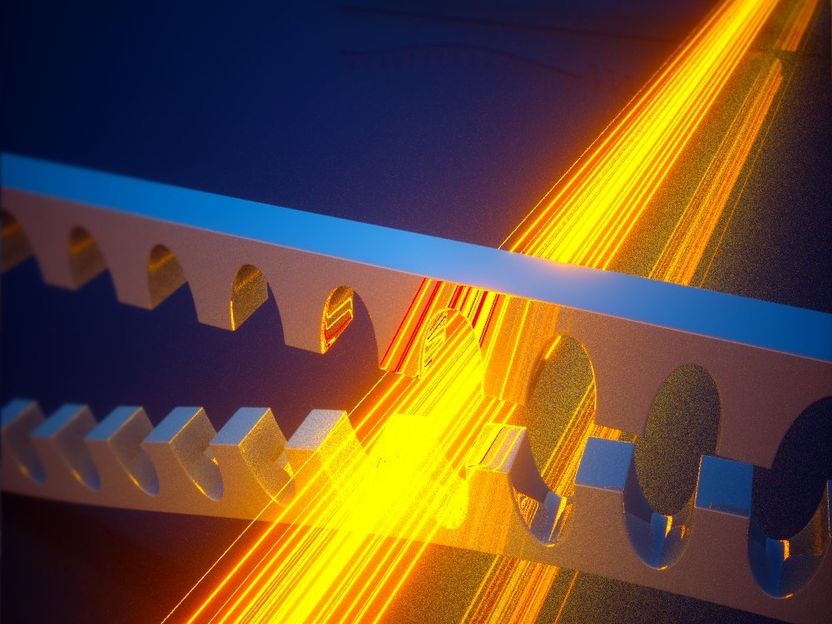

New topological metamaterial amplifies sound waves exponentially