Shipping of the future: biodegradable antifouling coatings for clean seas

Interdisciplinarity as the key to sustainable material innovation

More sustainable antifouling coatings for ships are in demand. These innovative solutions should largely dispense with biocides and still withstand the challenges of maritime use. As part of the "BioSHIP" project funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) under the "Maritime Research Program", industry and science are working together to develop such environmentally friendly coatings. The biodegradable, self-polishing coatings should not only offer the same functionality as conventional products, but also minimize the release of toxic heavy metals and microplastics into the sea - a major step towards green shipping.

Coated Rudder blade: Despite the protective coating, there is barnacle growth, whose calcareous shells increase frictional resistance, increase fuel consumption, and can impair the rudder function.

© Fraunhofer IFAM

At over 30,000 square meters, the hull area of a medium-sized container ship can reach impressive dimensions. These extensive areas provide an ideal habitat for a variety of sessile organisms such as algae, barnacles and mussels. However, this colonization causes considerable problems for shipping. The growth, also known as biofouling, increases the flow resistance and leads to increased fuel consumption. This not only results in higher costs, but also contributes to an increase in carbon dioxide emissions. There is also a risk that introduced species could endanger the stability of marine ecosystems. To combat biofouling, antifouling coatings containing biocides are generally used – highly effective but often poorly degradable substances that have undesirable effects on water quality and aquatic organisms. For this reason, a large number of different approaches have been pursued in recent decades to develop more environmentally friendly ship coatings. Nevertheless, many self-polishing coating systems are based on problematic heavy metal salts that end up in water bodies and sediments.

From biocide-containing coatings to an environmentally friendly alternative

Biocidal coatings currently dominate the market. Through the targeted release of heavy metals, they are particularly effective against biofouling and account for about 80 percent of the applications used worldwide. The most commonly used self-polishing coatings also contain special polymers that break down on contact with water and thus always create a smooth surface, which makes colonization more difficult. The aim of the "BioSHIP" project is to develop a biodegradable, self-polishing ship coating that requires significantly lower levels of toxic heavy metals and minimizes environmental pollution. A promising approach for biodegradable, self-polishing coatings lies in the targeted control of the degradation rate in order to ensure a long-lasting antifouling effect. The project focuses on more sustainable formulations, including the use of bio-based polymers such as polylactide (PLA) or chitosan derivatives, which degrade in a controlled manner under marine conditions without leaving harmful residues. The balance between durability and biodegradability can be further optimized through the targeted synthesis of functionalized additives.

Interdisciplinarity as the key to sustainable material innovation

The project combines expertise from various disciplines to ensure targeted development. Material development focuses on biodegradable polymers and innovative coating components that meet the requirements for durability, fouling protection, and environmental compatibility. At the same time, the coatings are tested under real marine conditions, including different geographical regions, to ensure broad applicability. In addition, the project partners are conducting ecotoxicological studies to ensure that the materials developed have no harmful effects on organisms.

Through close cooperation between science and industry, the project shows how technological innovations can help to tackle global challenges. The results of "BioSHIP" could not only make a valuable contribution to the maritime industry, but also provide impetus for other sectors that rely on sustainable material solutions. Especially in regions with strict environmental regulations, such as Europe, Australia, New Zealand or parts of the USA, the technology could establish new standards and decisively drive the transition to more sustainable shipping.

Project partners

- Momentive Performance Materials GmbH (Coordinator)

- Dr. Brill + Partner GmbH (Institute for Antifouling and Biocorrosion, Norderney)

- Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM

- Hydrotox GmbH

Most read news

Other news from the department science

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

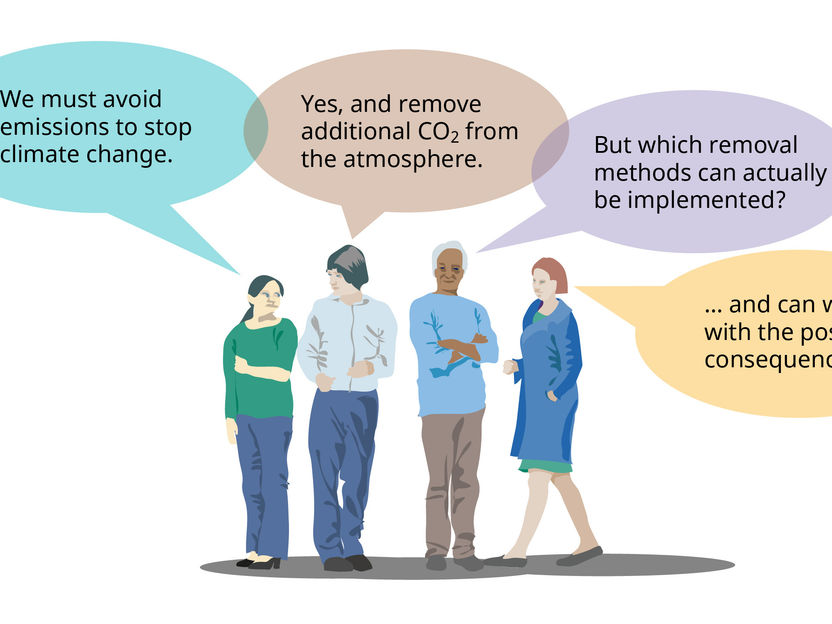

CO₂ removal and storage: Which options are feasible and desirable? - A new framework helps to evaluate the feasibility of ocean-based CO2 removal processes and assesses their impact on humans and nature

Sustainable plastics containing flame retardants for use in closed-loop applications - New ways for recycling quotas

H.C. Starck Tungsten receives millions in funding for battery recycling - Over 60 million euros for the recycling of battery black mass

Swiss start-up gives yesterday's plastics a new purpose - DePoly to launch 500-tonne-per-year showcase plant, as it secures $23M

Sensor-Based Waste Sorting Reduces Number of Battery Fires in Recycling Plants

World Leading E-Waste, Battery, Metal, ITAD & Circular Electronics Conference Reveals 2025 Agenda

Critical raw materials from electrolysers back into the cycle - Researchers succeed in recycling functional materials for hydrogen production

Less than a month to go: E-Waste World, Battery Recycling, Metal Recycling, ITAD & Circular Electronics Conference & Expos 2025 enter final phase

Climate protection in the spin cycle - Science and industry jointly test a new technology for CO2 capture in the cement industry

Milestone in diaper recycling: degrading cellulose in composite materials succeeded - Breakthrough with the help of enzymes

Siemens and TURN2X join forces to scale up green energy production - Partnership directly contributes to expanding the availability of green energy alternatives