Sustainable plastics containing flame retardants for use in closed-loop applications

New ways for recycling quotas

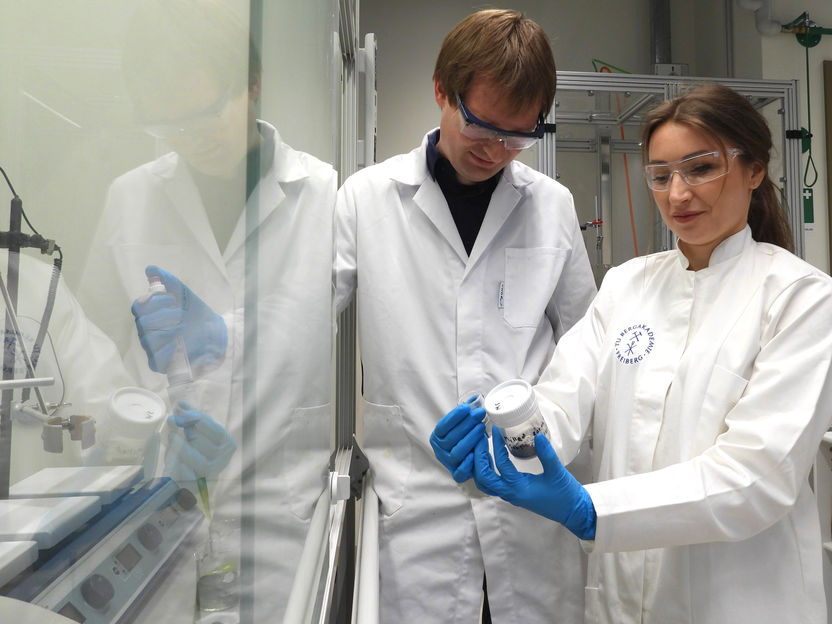

The development of high-quality, halogen-free flame retardants (hffr) for recycled plastics to meet increasing recycling quotas is a major challenge. The Fraunhofer Institute for Structural Durability and System Reliability LBF is looking for partners for the project "hffr-Up2Cycle". The main objective is to upgrade PCR materials with halogen-free flame retardants (hffr) and to investigate these materials through the simulation of closed-loop processes for plastics containing flame retardants in the sections of electronics, automotive, construction and cable applications. The project is aimed at OEMs, manufacturers of plastic components, raw material suppliers and compound developers.

Achieve recycling rates through targeted re-stabilization

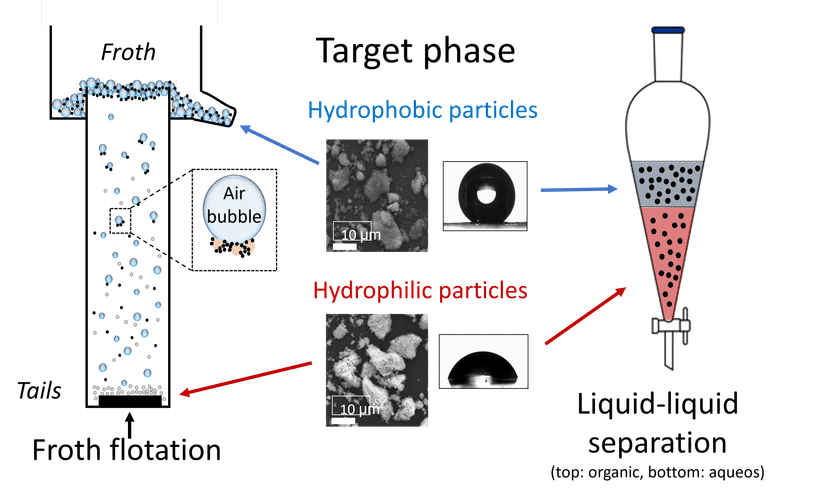

In view of the recycling quotas envisaged in many industries and the associated increasing demand for recycled plastics, "hffr-Up2Cycle" focuses on upgrading them for use in high-quality hffr applications. The tailor-made re-stabilization of the recycled plastics used is intended to show how the targeted upgrading of recyclates can be used to achieve recyclate quotas and circular applications for plastics containing flame retardants. The project investigates the flammability of processed and recycled PCR materials such as polyolefins (PP, PE), PET, PC/ABS, PA and flexible PU foam.

The aim is to optimize the formulations to achieve the best flame retardant ratings as well as mechanical and long-term properties. Another focus is to identify strategies to improve available recyclates coming from low value streams into selected higher value flame retardant applications. The selection and characterization of commercially available PCR materials and the analytical evaluation of flame retardants in PCR polymers, including testing of closed-loop processes, are driving the project.

Improvement of flame retardant ratings and mechanical properties

Fraunhofer scientists are looking for partners with whom they can implement research scientists' findings in a demand-oriented manner, thus closing the gap between basic research and industrial development. Together, they develop customized solutions for the current challenges in the plastics industry.

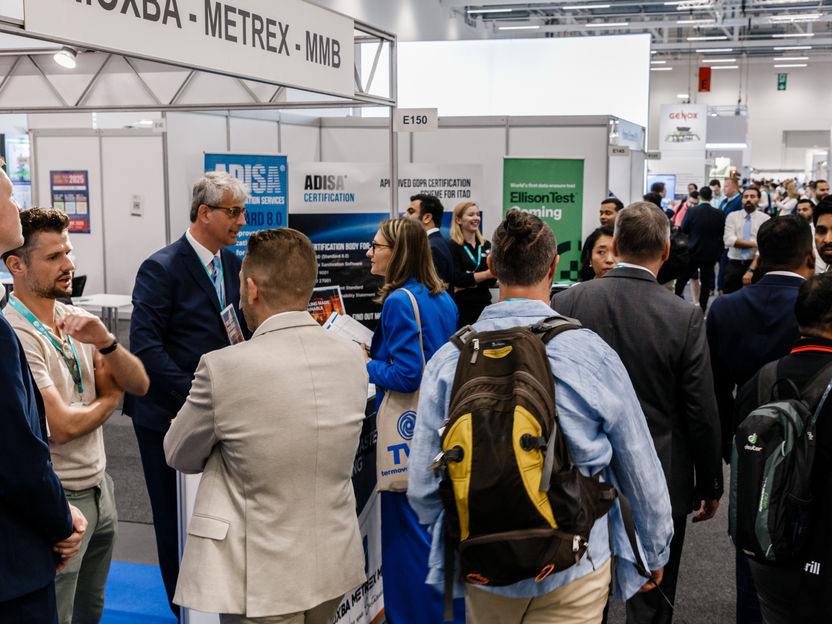

OEMs and manufacturers of plastic components, particularly in the automotive, electrical and electronics and construction sections, raw material suppliers, compound developers and manufacturers of plastic recyclates, can benefit from the results. Those responsible for regulatory compliance (PRRC) and industry associations along the value chain are also addressed.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

H.C. Starck Tungsten receives millions in funding for battery recycling - Over 60 million euros for the recycling of battery black mass

Swiss start-up gives yesterday's plastics a new purpose - DePoly to launch 500-tonne-per-year showcase plant, as it secures $23M

Sensor-Based Waste Sorting Reduces Number of Battery Fires in Recycling Plants

World Leading E-Waste, Battery, Metal, ITAD & Circular Electronics Conference Reveals 2025 Agenda

Critical raw materials from electrolysers back into the cycle - Researchers succeed in recycling functional materials for hydrogen production

Less than a month to go: E-Waste World, Battery Recycling, Metal Recycling, ITAD & Circular Electronics Conference & Expos 2025 enter final phase

Climate protection in the spin cycle - Science and industry jointly test a new technology for CO2 capture in the cement industry

Milestone in diaper recycling: degrading cellulose in composite materials succeeded - Breakthrough with the help of enzymes

Siemens and TURN2X join forces to scale up green energy production - Partnership directly contributes to expanding the availability of green energy alternatives

Renewable Materials Conference 2025: Nominees for the Innovation Award Unveiled

New method for sustainable recycling of rare earths from electrolysers - Turning old into new