Swiss start-up gives yesterday's plastics a new purpose

DePoly to launch 500-tonne-per-year showcase plant, as it secures $23M

Swiss cleantech scale-up prepares to demonstrate industrial-scale implementation of its revolutionary technology that transforms plastic waste into virgin-quality raw materials without fossil fuels.

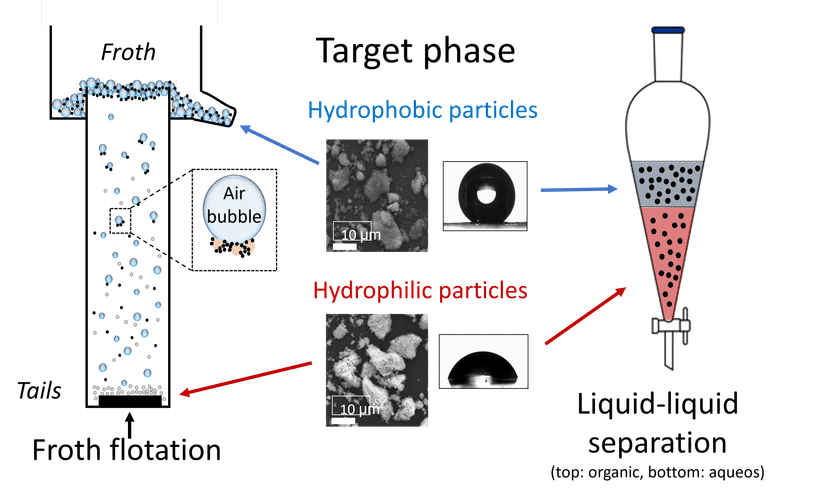

Every year, millions of tons of PET and polyester waste end up in landfills or are incinerated, yet sustainable recycling solutions remain limited. DePoly - the leading sustainable PET-to-raw-material recycling company – announces the upcoming launch of a 500-tonne-per-year showcase plant in Monthey, Switzerland this summer, representing a critical step in the company's journey from laboratory breakthrough to industrial-scale implementation.

The facility will demonstrate DePoly's proprietary process that converts PET and polyester waste into virgin-quality raw materials without fossil fuels. Imagine a world where discarded items – from polyester shirts to water bottles – are not wasted anymore but resources transformed back into the building blocks for new products. After all, revolutionizing an industry isn't just about creating new technology – it's about proving it works at scale.

DePoly’s technology has already demonstrated its commercial impact through collaborations with some of the world’s leading companies—not only in fashion, like Odlo, but also in cosmetics and the broader consumer goods industry, including innovators such as PTI. Through these partnerships, DePoly has validated the quality of its recycled monomers by transforming PET waste into new bottles, high-performance textile fibers, and cosmetic packaging. This proves that DePoly’s recycled materials can meet, and even exceed, the highest standards of purity and performance across a wide range of industries.

By delivering oil-equivalent monomers, DePoly’s technology sets a new benchmark for circularity, offering a genuine alternative to virgin materials.

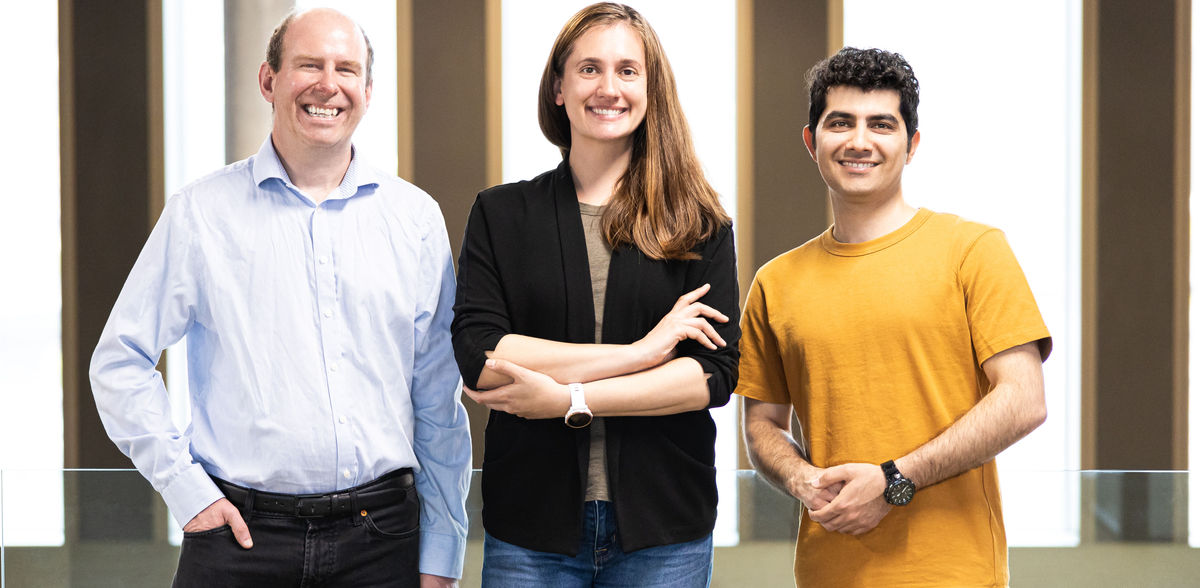

"The upcoming showcase plant validates our roadmap to creating a truly circular plastics market. Following our pilot and showcase plant, our next goal is to scale our operations to industrial size with a first of a kind commercial plant based on our technology", said Samantha Anderson, Co-founder & CEO of DePoly.

DePoly is ramping up with world-class innovators, bold thinkers and cutting-edge know-how—taking their pilot victory to industrial scale demands nothing less than unstoppable ambition. The company is planning to build a commercial plant in 2027 that will process significantly larger volumes of PET and polyester waste – a major leap in redefining recycling and advancing the circular economy, as DePoly strives to become the global leader in sustainable, circular plastics.

To further accelerate this expansion, DePoly has secured a total of $23 million in seed funding with MassMutual Ventures joining a second closing of its round. The expanded investor base positions DePoly as one of the biggest recycling technology companies in Europe, with more than $30 million raised across two rounds and grants. MassMutual Ventures joins existing investors, including Founderful, ACE & Company, Angel Invest, Zürcher Kantonalbank, BASF Venture Capital, Beiersdorf Venture Capital, and Syensqo.

"DePoly's proven technology is a game changer addressing a crucial industrial and societal challenge. This raise and the showcase plant opening are advancing DePoly's position as a leader in plastics recycling," said Alix Brunet, Europe Lead at MassMutual Ventures.

David Hanf, who joined DePoly in 2024 as CFO, brings extensive experience from European scale-ups including Smava and Thermondo—Germany’s largest B2C heat service company. Both an entrepreneur and an executive, he adds: "We are convinced our technology is one of the fastest to scale and will allow us to compete with virgin pricing at scale, a key factor for success. We are happy to have expanded our investor base to the US with MassMutual Ventures as we want to build a global champion."

By transforming discarded plastics into high-quality raw materials, DePoly reduces reliance on fossil resources, minimizes waste, and paves the way for a circular materials industry. Recognized as a Technology Pioneer by the World Economic Forum and a winner of the 2024 Top 100 Swiss Startup Award, DePoly proves that sustainable innovation is not only possible – it's happening now.

Most read news

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.

Last viewed contents

Sensor-Based Waste Sorting Reduces Number of Battery Fires in Recycling Plants

World Leading E-Waste, Battery, Metal, ITAD & Circular Electronics Conference Reveals 2025 Agenda

Critical raw materials from electrolysers back into the cycle - Researchers succeed in recycling functional materials for hydrogen production

Less than a month to go: E-Waste World, Battery Recycling, Metal Recycling, ITAD & Circular Electronics Conference & Expos 2025 enter final phase

Climate protection in the spin cycle - Science and industry jointly test a new technology for CO2 capture in the cement industry

Milestone in diaper recycling: degrading cellulose in composite materials succeeded - Breakthrough with the help of enzymes

Siemens and TURN2X join forces to scale up green energy production - Partnership directly contributes to expanding the availability of green energy alternatives

Renewable Materials Conference 2025: Nominees for the Innovation Award Unveiled

New method for sustainable recycling of rare earths from electrolysers - Turning old into new

Air Products and thyssenkrupp Sign Exclusive Strategic Cooperation Agreement - World-Scale Electrolysis Plants to Generate Green Hydrogen

Pfeiffer Vacuum Opens New Leak Detection and Vacuum Technology Facility in Indianapolis, Indiana