thyssenkrupp Uhde and Praj Industries Ltd join forces to revolutionize polylactic acid production and circular economy

End-to-end offering for PLA (polylactic acid) production

thyssenkrupp Uhde’s polymer specialists Uhde Inventa-Fischer (UIF), a subsidiary of the global leader in chemical engineering and construction, and Praj Industries Limited (PIL), a global leader in industrial biotechnology solutions, announced a strategic partnership to jointly offer an end-to-end integrated technology for the production of polylactic acid (PLA). This strategic partnership offers a unique, seamless solution that sets them apart in the arena of bioplastics.

The indiscriminate use of fossil-based plastics and the often irresponsible disposal, especially of single-use plastics (SUPs), call for urgent, innovative, and sustainable solutions. Polylactic acid (PLA), as a sustainable alternative to conventional plastics holds significant potential in advancing a circular bioeconomy. To meet this global need, PIL and UIF are leveraging their combined expertise in industrial biotechnology and chemical engineering to enhance PLA technology, ensuring efficient, cost-effective and sustainable production processes.

Nadja Håkansson, CEO thyssenkrupp Uhde: “We see a perfect match of two world-leading technologies: Uhde’s PLAneo® process can now be offered as an integrated solution with Praj Industries’ lactic acid production. Together, we can design and deliver complete PLA plants. Our joint vision is a competitive solution to replace conventional plastics with sustainable alternatives.”

Dr. Pramod Chaudhari, Founder Chairman, at Praj Industries: “Praj’s Bioprism® portfolio for renewable chemicals and materials, with a focus on bioplastics, underscores our commitment to a sustainable future. Our strategic partnership with Uhde marks a significant step in driving the global shift toward a circular economy by enabling cost-effective biomanufacturing and the establishment of biorefineries. With our award-winning proprietary PLANERA™-technology and this collaboration, we aim to tackle the challenges posed by fossil-based plastics and contribute to a more sustainable planet with innovative, bio-based solutions.”

The partnership will be able to offer an end-to-end integrated technology, covering the entire PLA production process from feedstock conversion to polymer production. Different grades of Lactic acid can be produced from this technology which find applications in food and industrial sectors. A broad range of PLA grades can be produced, addressing the diverse requirements of various industries such as packaging, textiles, and hygiene supplies. Both companies have a strong global presence, enabling them to deliver innovative solutions to customers worldwide and adapt to practically any agricultural feedstock containing either starch or sugar, including second generation feedstocks based on non-food raw materials.

A shared commitment to sustainability drives the partnership, focusing on developing environmentally friendly and socially responsible solutions. Praj recently inaugurated India’s first-of-its-kind 'Demonstration Facility for Biopolymers' near Pune, India, where it is producing lactic acid and lactide. This facility will serve as a crucial platform for testing and validating the joint offering, enabling the partners to showcase the potential of PLA and accelerate its commercialization.

Most read news

Organizations

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

BASF invests in new semiconductor-grade sulfuric acid plant in Ludwigshafen - New capacity meets growing demand for the manufacturing of chips in Europe

WACKER starts production of hybrid polymers at its Nünchritz site - Expansion measure underscores focus on specialties offering high innovation potential

WACKER commissions new plants for specialty silicones in China - WACKER continues its successful “in China for China” strategy with this expansion

AkzoNobel takes next steps to optimize its European industrial footprint

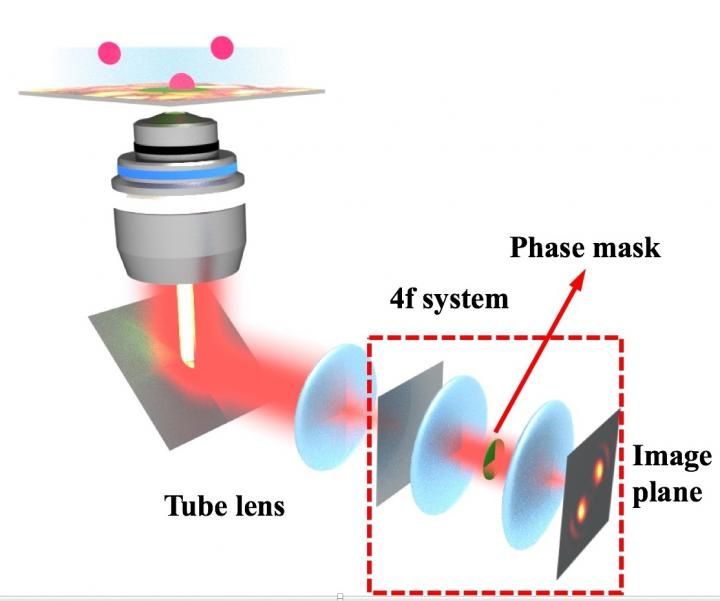

Shaping light lets 2D microscopes capture 4D data - Invention adds new dimension to fluorescent microscopy

Illinois Tech ‘spinout’ startup Influit Energy has created the world’s first rechargeable, safe, electric fuel - “Discharged fluid can be returned to a recharge/refuel station for recharging or be charged inside the device by plugging into the power source”

Clean-tech startup launches to create grid-scale battery infrastructure for greater use of wind and solar power - An innovative redox-flow battery

BASF’s Process Catalysts research team receives 2023 Edison Patent Award for novel adsorbent - Awarded BASF U.S. patent covers a novel method for reducing impurities in petrochemicals

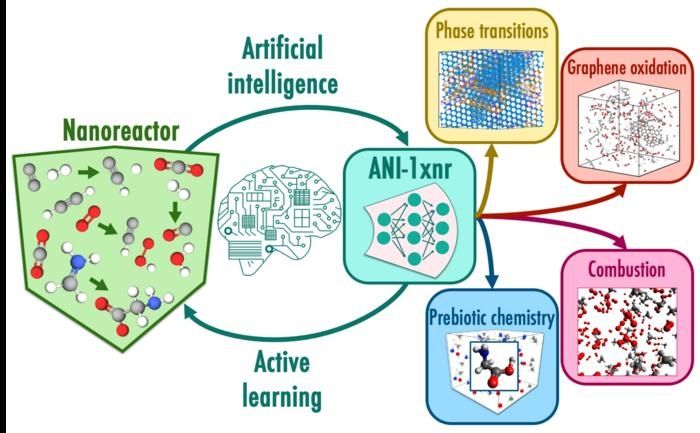

Artificial intelligence helps explore chemistry frontiers - Machine learning helps simulate reactive molecular dynamics for research and discovery

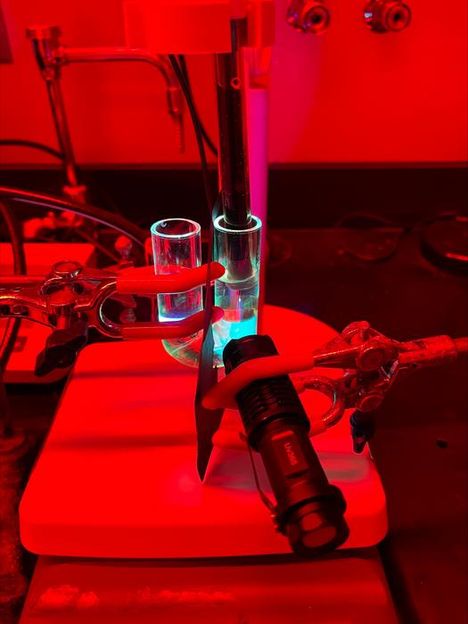

Self-powered pump harnesses light and chemistry to target, capture pollutants - Dartmouth team develops light-controlled pump with potential applications for environmental cleanup

Chemours Opens State-of-the-Art Battery Innovation Center to Accelerate the Evolution of Electric Vehicle Batteries - The facility will enable more sustainable, cost-effective, and high-performing EV batteries