WACKER commissions new plants for specialty silicones in China

WACKER continues its successful “in China for China” strategy with this expansion

WACKER is responding to rising demand for high-quality specialty silicones in China by expanding its production capacities at its Zhangjiagang site. The Group held a ceremony to celebrate the mechanical completion of the facilities. Going forward, the new production complex will manufacture silicone fluids, silicone emulsions and silicone elastomer gels. Production is to be ramped up over the coming months. As planned, WACKER has invested a low three-digit million euro amount in the expansion project.

“Our investment here in Zhangjiagang shows that we are committed to our successful ‘in China for China’ strategy, even in economically challenging times”, Executive Board member Christian Kirsten said at the ceremony marking the completion of the production complex. WACKER has been operating successfully in China for more than 30 years. It currently generates 37 percent of its sales in Asia, with China accounting for around half of this amount. “By expanding our silicone capacities in Zhangjiagang, we are able to strengthen our specialties business. This secures our market position as a leading manufacturer of silicones in China”, Kirsten pointed out.

The products manufactured in the new facilities include high-purity functional and non-functional silicone fluids as well as silicone emulsions. Selected production lines will comply with GMP (Good Manufacturing Practice) manufacturing, creating products that can be used in the cosmetics industries. Another new development in Zhangjiagang is the production of silicone elastomer gels, up to now only manufactured in Germany and in India. Elastomer gels are particularly in demand from Chinese manufacturers of cosmetics and personal-care products.

“The expansion shows that we are determined to always stay ahead of market trends and to meet diverse consumer needs,” explained Alvin Hu, President of WACKER Greater China, during the ceremony. The project is the largest single investment in the site’s 15-year history. “This project is a strategic investment in the future. By increasing our production capacities, we can support growth in China over the long term. What is more, we are now able to support our customers’ product innovations and respond more quickly to current market requirements,” he emphasized.

Silicone fluids are frequently used in the consumer goods, textile and construction sectors, while silicone emulsions and silicone elastomer gels are typically used in textiles, cosmetics and personal-care applications, including makeup, shampoos and fabric softeners. Functional silicone fluids are important starting materials for industrial applications such as release coatings or impregnating agents. Other applications for silicone fluids include their use as additives for construction, paper, paints and coatings.

Zhangjiagang is one of WACKER’s largest fully integrated production sites. From here the company supplies rapidly growing Asian markets with a wide array of downstream silicone products such as sealants, elastomers and fluids. Silicones from WACKER are used not only in traditional fields of application, such as the textile, leather and fiber industries, as well as for chemical processes and coatings. They also play a key role in particularly innovative sectors, such as electromobility, the generation of renewable energy, and medical technology.

Most read news

Organizations

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

AkzoNobel takes next steps to optimize its European industrial footprint

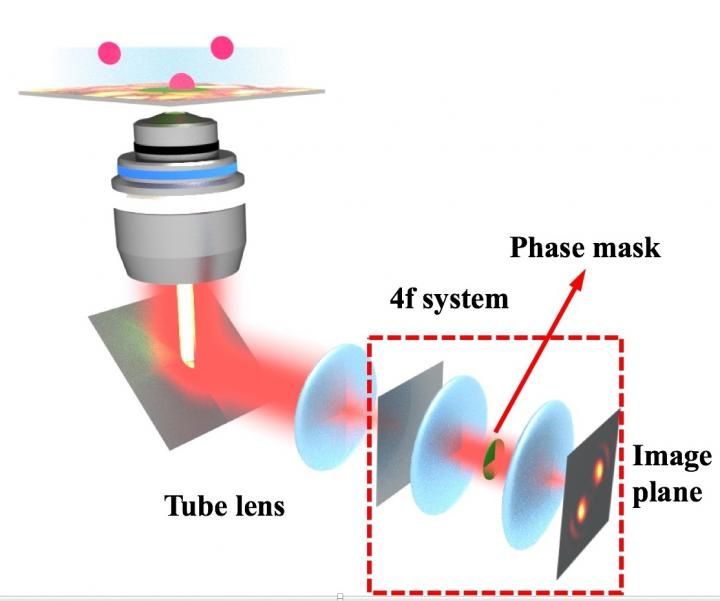

Shaping light lets 2D microscopes capture 4D data - Invention adds new dimension to fluorescent microscopy

Illinois Tech ‘spinout’ startup Influit Energy has created the world’s first rechargeable, safe, electric fuel - “Discharged fluid can be returned to a recharge/refuel station for recharging or be charged inside the device by plugging into the power source”

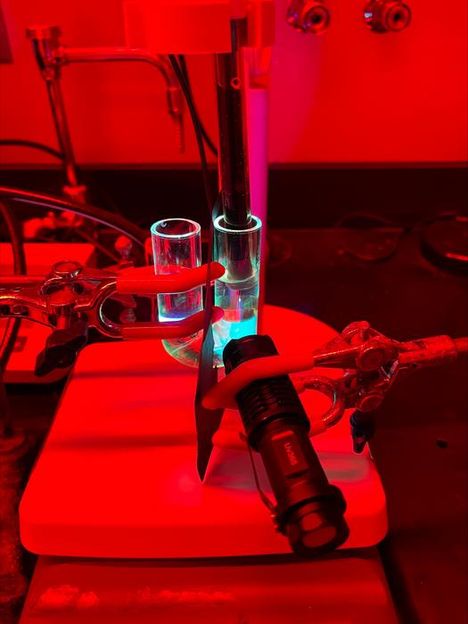

Clean-tech startup launches to create grid-scale battery infrastructure for greater use of wind and solar power - An innovative redox-flow battery

BASF’s Process Catalysts research team receives 2023 Edison Patent Award for novel adsorbent - Awarded BASF U.S. patent covers a novel method for reducing impurities in petrochemicals

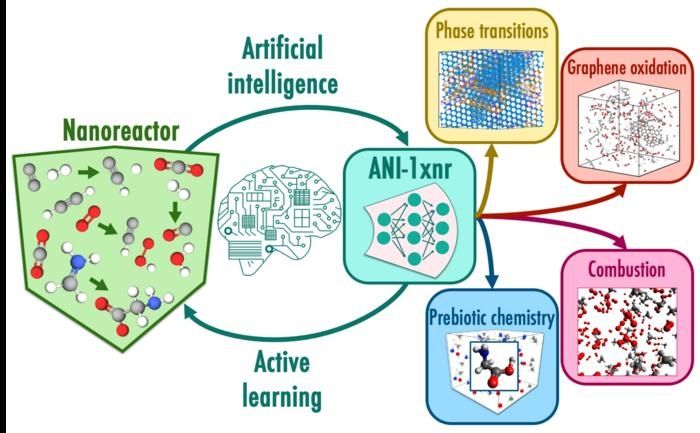

Artificial intelligence helps explore chemistry frontiers - Machine learning helps simulate reactive molecular dynamics for research and discovery

Self-powered pump harnesses light and chemistry to target, capture pollutants - Dartmouth team develops light-controlled pump with potential applications for environmental cleanup

Chemours Opens State-of-the-Art Battery Innovation Center to Accelerate the Evolution of Electric Vehicle Batteries - The facility will enable more sustainable, cost-effective, and high-performing EV batteries

Nobel Prize in Chemistry: How protein discoveries benefit research at BASF - Computational protein design and protein structure prediction speed up day-to-day research

BASF inaugurates new Catalyst Development and Solids Processing Center in Ludwigshafen - Expansion of global catalyst development activities

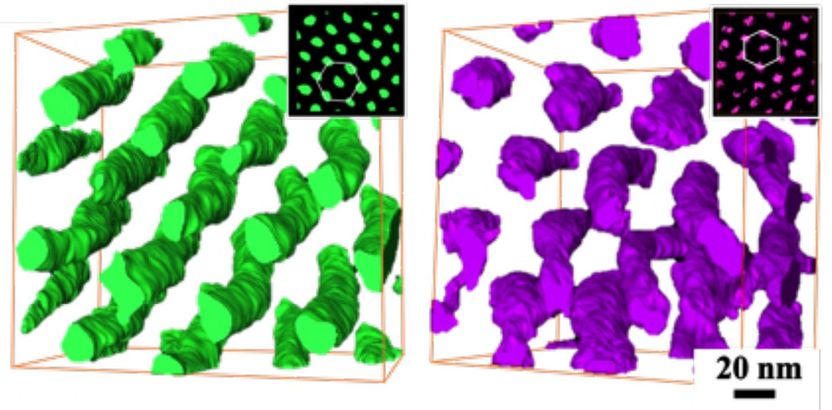

Lefty or righty molecules lend a hand to material structures - Effort to build bottom-up chiral polymers with unique functions