WACKER starts production of hybrid polymers at its Nünchritz site

Expansion measure underscores focus on specialties offering high innovation potential

Chemicals group WACKER has commenced production of hybrid polymers at its Nünchritz site. The new production facility is currently undergoing ramp-up. Hybrid polymers serve as binders for high-quality adhesives and sealants and are extremely popular because they are easy to use. Such binders are increasingly being employed by manufacturers of construction and assembly adhesives, parquet-flooring adhesives or liquid waterproofing membranes for roofs and balconies. The alpha-silane-terminated hybrid polymers from WACKER enable the formulation of tin-free, consumer-friendly products. The costs of the new production facility are in the double-digit million euros range. As a result of the investment, 50 new jobs have been created at the site.

The new high-speed facility will replace the existing production plant at the Burghausen site and will substantially boost production capacity for hybrid polymers. “With annual growth rates of well over five percent in some cases, the market for hybrid polymers is extremely attractive for us,” says Managing Board member Christian Kirsten. WACKER is already a world-leading manufacturer of silane-terminated polymers, he adds. “Expanding our production puts us in a position to support the growth of our customers. The facility thus aligns with our strategy of increasingly focusing on tailor-made specialties that offer great innovation potential, high vertical integration and high customer benefit.”

The ultra-modern production line at the Nünchritz site features a range of technical innovations, making it truly state of the art. The highly integrated combination of key working steps within the building keeps distances short and makes for highly efficient continuous production processes. “The new facility’s production capacity will increase our output many times over,” says Tom Koini, Head of the Silicones business division. It can also be expanded to accommodate future growth, he adds. “If the market continues to grow as dynamically as before, we will be able to significantly boost our production capacity once again.”

Hybrid polymers rank among the business division’s most important growth fields. Offered under the name GENIOSIL® STP-E, the products serve as silane crosslinking binders for formulating high-performance adhesives and sealants for industrial and construction applications and, more recently, for liquid waterproofing membranes.

Since hybrid polymers based on WACKER’s proprietary alpha-silane technology can also be used to produce tin-free products, they are environmentally and consumer-friendly. “Aspects like these, alongside performance, are becoming more and more important in the formulation of adhesives and sealants. They are what makes our hybrid polymers so attractive to customers,” says Koini. “The alpha-silane technology allows us to develop customized binders for a wide variety of adhesive types. Demand for such products will continue to see strong growth in the coming years.”

The new hybrid production facility is also good news for the region, as 50 new jobs are being generated. With 1,600 employees, WACKER is the largest chemical employer in Saxony.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

WACKER commissions new plants for specialty silicones in China - WACKER continues its successful “in China for China” strategy with this expansion

AkzoNobel takes next steps to optimize its European industrial footprint

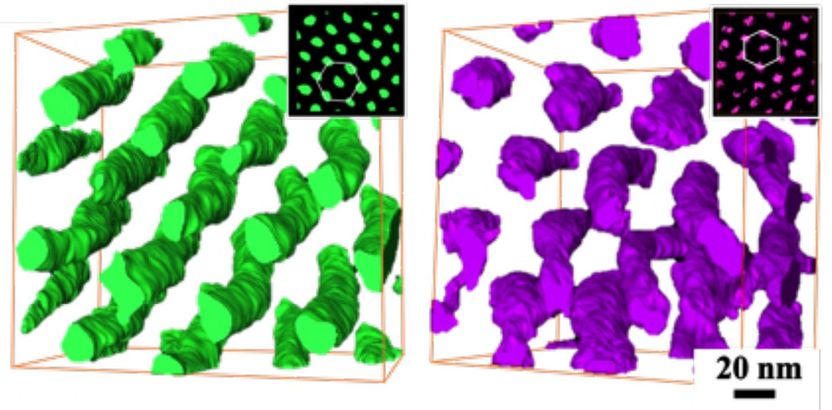

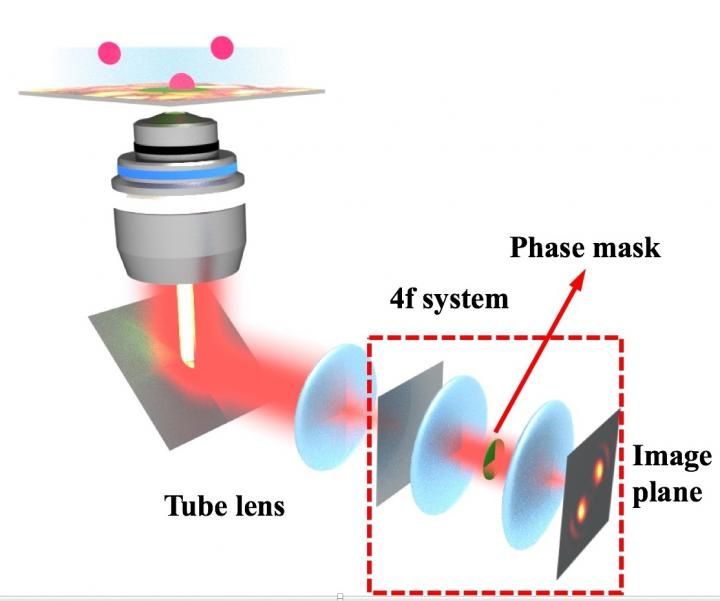

Shaping light lets 2D microscopes capture 4D data - Invention adds new dimension to fluorescent microscopy

Illinois Tech ‘spinout’ startup Influit Energy has created the world’s first rechargeable, safe, electric fuel - “Discharged fluid can be returned to a recharge/refuel station for recharging or be charged inside the device by plugging into the power source”

Clean-tech startup launches to create grid-scale battery infrastructure for greater use of wind and solar power - An innovative redox-flow battery

BASF’s Process Catalysts research team receives 2023 Edison Patent Award for novel adsorbent - Awarded BASF U.S. patent covers a novel method for reducing impurities in petrochemicals

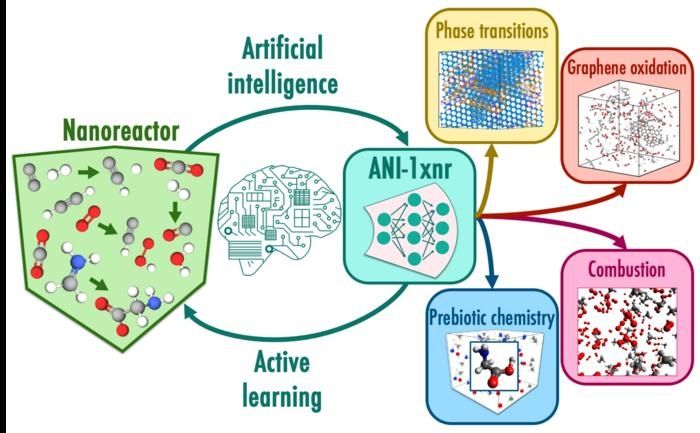

Artificial intelligence helps explore chemistry frontiers - Machine learning helps simulate reactive molecular dynamics for research and discovery

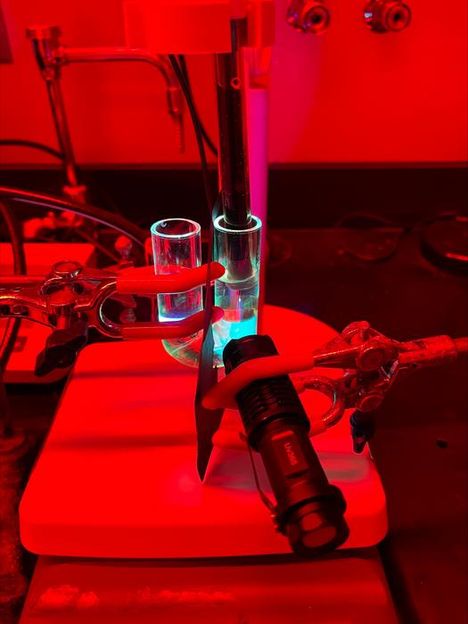

Self-powered pump harnesses light and chemistry to target, capture pollutants - Dartmouth team develops light-controlled pump with potential applications for environmental cleanup

Chemours Opens State-of-the-Art Battery Innovation Center to Accelerate the Evolution of Electric Vehicle Batteries - The facility will enable more sustainable, cost-effective, and high-performing EV batteries

Nobel Prize in Chemistry: How protein discoveries benefit research at BASF - Computational protein design and protein structure prediction speed up day-to-day research

BASF inaugurates new Catalyst Development and Solids Processing Center in Ludwigshafen - Expansion of global catalyst development activities